Categories

- Trolleys

- Trolleys

-

Industrial Platform Trolleys

Industrial Platform Trolleys

-

Medical Stainless Steel Trolleys

Medical Stainless Steel Trolleys

-

Order Picking Trolleys

Order Picking Trolleys

-

Trolleys For Wet Conditions

Trolleys For Wet Conditions

-

Hand Trolleys and Hand Trucks

Hand Trolleys and Hand Trucks

-

Industrial Multi Tier Trolleys

Industrial Multi Tier Trolleys

-

Office Trolleys

Office Trolleys

-

Signature Series Trolleys

Signature Series Trolleys

-

Trust Industrial Trolleys

Trust Industrial Trolleys

-

Dollies

Dollies

-

Load Skates

Load Skates

-

Trolley Accessories & Miscellaneous

Trolley Accessories & Miscellaneous

- Castors

- Castors

-

General Duty Grey Rubber Castors

General Duty Grey Rubber Castors

-

Industrial Grey Rubber Caster

Industrial Grey Rubber Caster

-

Industrial Blue Rubber Castors

Industrial Blue Rubber Castors

-

Industrial White Nylon Castors

Industrial White Nylon Castors

-

Industrial Urethane Castors

Industrial Urethane Castors

-

Heavy Duty Low Profile Castors

Heavy Duty Low Profile Castors

-

Heavy Duty Urethane Castors

Heavy Duty Urethane Castors

-

Stainless Steel Castors

Stainless Steel Castors

-

Pneumatic Wheels & Castors

Pneumatic Wheels & Castors

-

Puncture Proof Wheels

Puncture Proof Wheels

-

Pallet Truck Wheel & Rollers

Pallet Truck Wheel & Rollers

-

Expanding Inserts

Expanding Inserts

-

Accessories

Accessories

- Chain & Synthetic Slings

- Chain & Synthetic Slings

-

Round Slings

Round Slings

-

Flat Slings

Flat Slings

-

Grade 80 & Grade 100 Chain & Gear

Grade 80 & Grade 100 Chain & Gear

-

Chain Slings

Chain Slings

- Traffic Management

- Traffic Management

-

Bollard and Cones

Bollard and Cones

-

Convex Mirrors

Convex Mirrors

-

Portable Barriers

Portable Barriers

-

Collision Protection

Collision Protection

Sign Up

Get Your 10% Off

For Your First Online Order!

Offer NOT applicable on Sale items

Hoisting Equipment

Introduction to Our Industrial Lifting Equipment

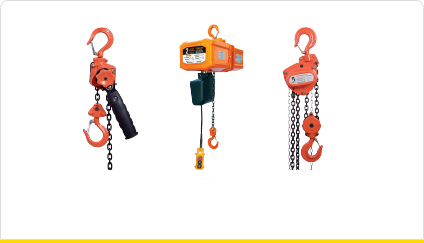

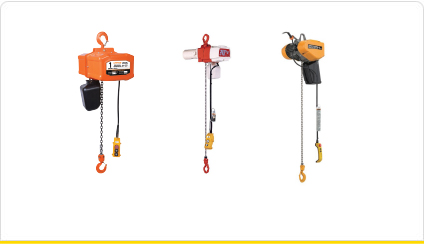

Lifting equipment is used in a variety of industries because it helps to improve efficiency in the workplace and reduce safety risks for employees. At Equip2Go, our wide selection of lifting equipment consists of lifting slings, chain and lever blocks, girder trolleys and clamps, crane scales, commercial rigging gear, shackles, and grade 80 alloy steel chain components.

Lifting Equipment Uses

With applications in businesses such as construction and building, mining, docks, manufacturing, warehouses, storage areas, factories and much more lifting equipment is a staple of many material handling and warehouse equipment industries. Chain blocks and lever blocks are an example of common tools that are used in the workplace to manually lift, lower or pull a load. As they are easy to operate and only require one person to use, they are commonplace in many industries such as power line work, pipe laying, confined space, forestry, automotive garages and heavy machinery work. Another example is rigging straps such as our round slings, flat slings and chain slings – all of which are used to provide support and help lift loads without risk of damage.

What to Consider When Looking for Lifting Equipment for Your Workplace

There are a few things to consider when choosing lifting equipment for your workplace. Firstly, no matter what item of lifting equipment you are looking for, always be sure to check its load capacity. For lifting slings and chain or lever blocks, also be sure to check their length, chain size and W.L.L (Working Load Limit). A major safety risk emerges if the total weight of the load (including the weight of any rigging equipment attached) exceeds this working load limit. Secondly, note that lever hoists are able to lift loads in most positions, including horizontally, whereas chain block hoists (also called block and tackles) can only lift loads vertically. Lastly, for rigging gear like shackles, keep in mind that bow shackles (also known as anchor shackles) have a rounded “O” shape that allows them to take loads from many directions without developing side load, whereas D/Dee-shackles (also known as chain shackles) have a “D” shape that is suitable for high loads primarily in line.

Safety Features of Our Lifting Equipment

There are a number of measures that you can take to ensure your workplace’s safety when using lifting equipment. For example, you should arrange for regular check-ups to be implemented. These check-ups entail periodic inspections conducted by a certified competent inspector at least once every 12 months, as well as frequent reviews performed by the employee prior to each use. For example, for chain and lever blocks, these frequent inspections should involve checking the load chain, hand chain, top and bottom hooks and the brake mechanism. For lifting slings, if there is any damage or wear and tear present, it is best to replace them since they cannot be repaired in most cases. Check-ups, both frequent and periodic, are necessary to sustain a safe working environment, as just because your lifting equipment is still working doesn’t mean that it is performing at its best and safest.

Moreover, ensure that you are choosing the right hoist strap for the right applications, not only in terms of individual dimensions, length and load capacity, but also in terms of the type. For delicate loads, flat webbing slings are a good choice, whereas for heavy and bulky loads, lifting chain slings will do the job. Additionally, our chain hoists are available in single-leg, 2-leg and 4-leg designs, each coming with shortening grab hooks and self locking hooks. They can also withstand harsh conditions such as high temperatures and exposure to chemicals and UV rays, all of which would otherwise damage synthetic sling belts (flat slings and round slings).

Besides these measures mentioned above, also be sure to not lift loads over other people and to not leave a suspended load unattended. By following these precautions, you can preserve the health and safety of all your employees.

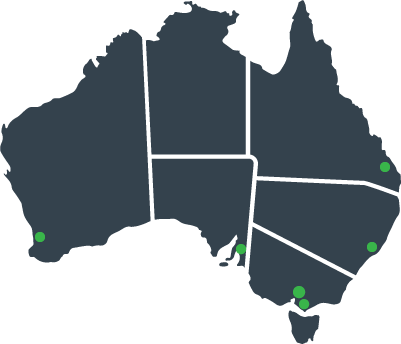

Our line of industrial lifting equipment enables safe and comfortable lifting of loads in your workplace. We deliver throughout Australia, with our head office situated in Dandenong South, Victoria, and further sales and warehousing operations located in Campbellfield (VIC), Wetherill Park (NSW), Canning Vale (WA) and Yatala (QLD).